Which of the Following Simplifies Pms Maintenance Procedures

ATTACH THE TAG TTO THE STEERING WHEEL OR IGNITON SOURCE. Maintenance activities are scheduled based on a specific measured runtime unit such as miles hours or level.

What Is Preventive Maintenance The Beginner S Guide To Running Pms

A planned maintenance system streamlines the planning documentation and implementation of maintenance work and surveys onboard ship.

. PM compliance 0825 x 100. Technical ship management system. Job Status Message Recipient.

The heart of every PM program is a recurring schedule based on manufacturers recommendations. Suppose we allow for up to 1 percent change in overall sensitivity due to changes in the sensor resistance. Which level of maintenance involves preventive and corrective procedures which are intended to restore equipment to ready status.

This is because all PM information resides in one place and can be associated with multiple assets. Only regularly scheduled preventive maintenance tasks should factor into your measurement. The PMS-1 is a 10-hour14-day inspection like the preventive maintenance daily of the phase maintenance method.

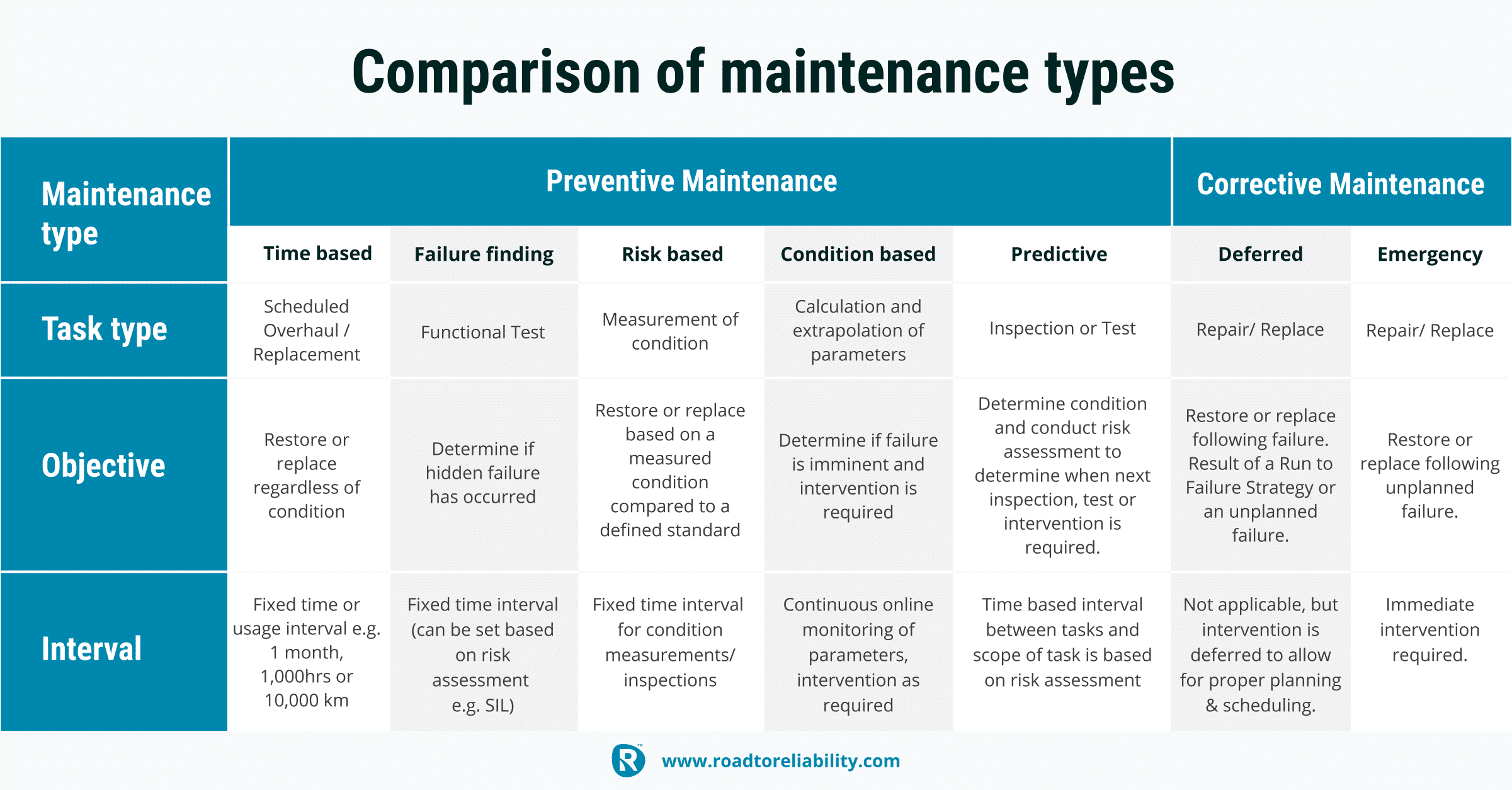

The maintenance procedures developed in accordance with what principles for planned maintenance are the minimum required to maintain equipment. 3 Scheduling and control of the performance of tasks. PMS simplifies maintenance procedures by Defining the maintenance required Scheduling its performance Describingthetoolsandmethodstobeusedand Providing for the detection and prevention of impending casualties.

Cleats on external weathertight doors. Reviews PMS assignments perform quality maintenance in accordance with procedural documentation and properly documents completion. PM compliance 165 200 x 100.

SHORT TERM MAINTENANCE WEEKLY INSPECTION AND GREASING WHEN POSSIBLE AS PER PMS. The system uses the address book number of the current user. FILL OUT BOTH SIDESS OF A DANGERDO NOT OPERATE TAG.

Process of planning directing and controlling the preventive maintenance of. Who has overall responsibility for ensuring maintenance is accomplished following 3-M system and quality maintenance procedures and that the 3-M system functions effectively within the command. Increases economy and simplifies records.

By having access to these metrics maintenance can make better decisions about how and when PMs are performed through automation. Door hinges on mast houses. Ventilation system flaps and ventilators.

PM compliance 165 completed PMs 200 scheduled PMs x 100. In direct current applications electrical power is calculated using Joules. A Maintenance person has which of the following responsibilities.

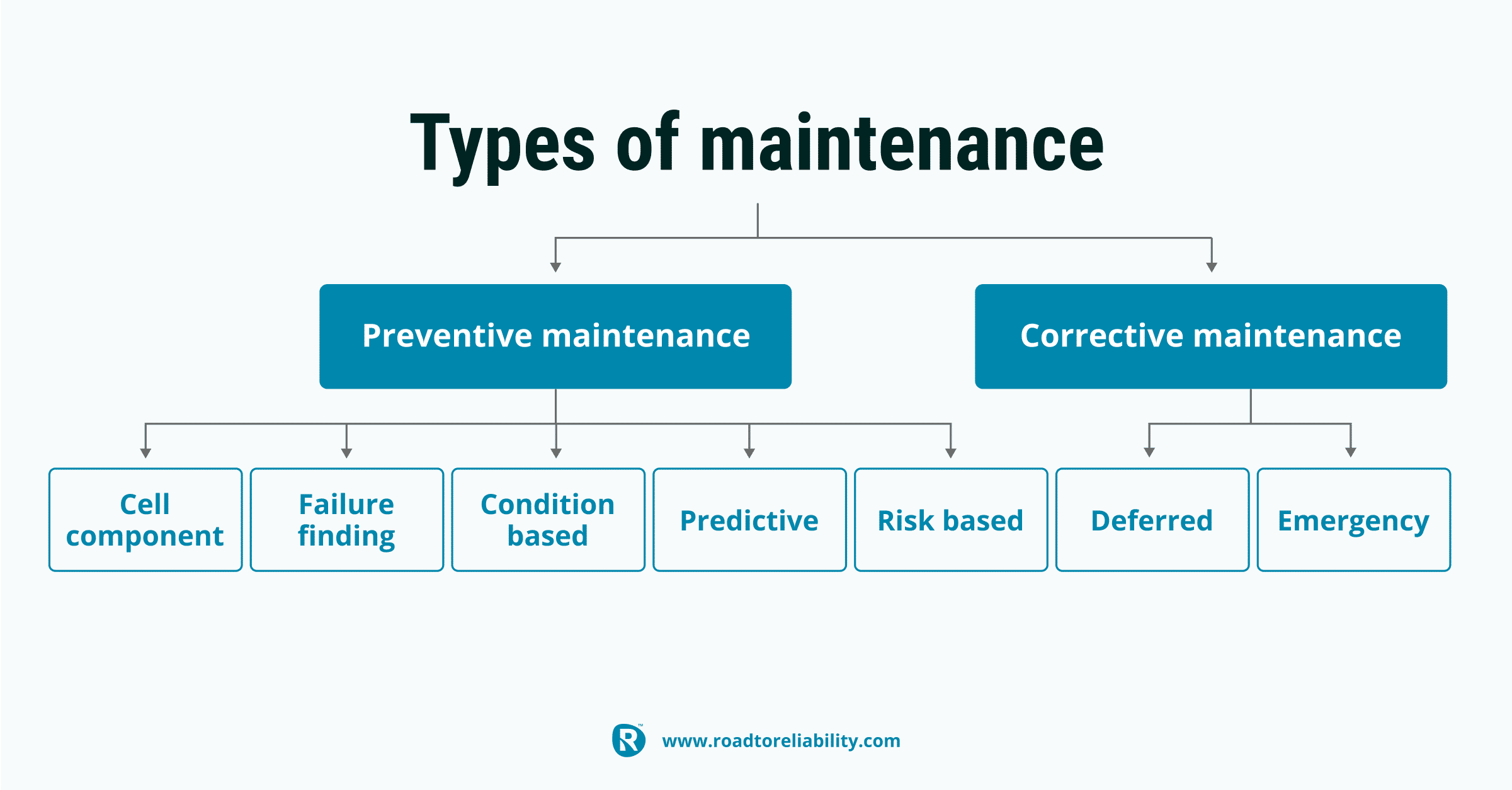

Status from maintenance rule. Planned maintenance breaks down into two categories. Maintenance activities are scheduled based on a specific date or a time interval such as number of days.

It stands for Planned Maintenance System. Terms in this set 15 Which category of preventive maintenance checks and services PMCS consists of before during and after vehicle operations. - Satisfied by higher level maintenance - c with line through it - Convenience related maintenance - M-3W ie every third week - Mandatory related maintenance - M-4W ie every fourth week - IEM delete marks - horizontal blue line - IEM status one and two - separated from operational by a.

Determine the specification for the input resistance of the signal conditioner. Report Date Date LOEP produced Force Revision FR Number Type Commander TYCOM Unit Ships hull number Unit Identification Code UIC and name Work Center Maintenance Index Page. By 314th Public Affairs Operations Center May 10 2012.

The LOEP Report No. Its important that you dont include every maintenance task into your calculations. The PMS simplifies the night audit by producing totals from departments and.

PM compliance 825. And supervisor include the following. Preventive Maintenance Checks Services.

Carrying out repairs needed when plant or equipment breaks down. Oil baths if any in winches and windlasses. The purpose of Army maintenance is to generate and regenerate combat.

The credits in the form of guest payments must be accounted for by reviewing the guests outstanding balances. Mechanical Engineering questions and answers. By implementing PM schedules on a CMMS maintenance teams decrease asset downtime and reduce costly repairs.

The two most common are. 5 Prevention or detection of hidden failures or malfunctions. Specify the status to which the PMs change.

Agencies have realised that the preventive maintenance program is a crucial component of any modern quality system because it ensures efficient GMP operationsThe purpose of this Standard Operating Procedure SOP is to describe the procedures involved in commissioning. Although this sounds like a simple process the procedure can be very involved. The Planned Maintenance System PMS is a.

Specify the address book number of the recipient of job status messages that result from the Update PM Schedule Status program R12807. Preventive Maintenance Services - manpower Parts Fuel Oil Lubricants as well as manufacture recommended checklist. It entails a visual inspection with some operational checks.

What type of signal- conditioning unit is required. Considerations used to determine PMS procedures. The planned maintenance system PMS.

PMS 5 provides a listing of the Maintenance Index Pages MIPs and system equipment not requiring PMS assigned to each Work Center. It depends on manufacturer recommendations and periodic inspection. 361 The manufacturing support systems are the procedures and systems used by a company to solve the technical and logistics problems encountered in planning the processes ordering materials controlling production and ensuring that the companys products meet required quality specifications.

1 Comprehensive procedures for planned maintenance of systems and equipment2 Minimum requirements for planned maintenance. Predicting from a history of breakdowns the life expectancy of parts bearings etc the tasks to be carried out and the frequency to be established. ShipManager Technical is the technical ship management system for both planned and unplanned maintenance defect reporting and technical asset and data management.

4 Description of the methods materials tools and personnel needed for maintenance. Wheels on steel hatch covers. As the term suggests preventive maintenance PM involves taking preventive actions to ensure pieces of equipment never come to an inconvenient and expensive halt.

Maintenance procedures that should be considered when preparing the planned maintenance program include. VISUALLY INSPECT THE AREA FOR CO-WORKERS OR EQUIPMENT THAT COULD BE HARMED WHEN EQUIPMENT IS RESTARTED. The preventive maintenance program was and still is a focal point of GMP inspection.

Measures and procedures to restore units to a desired level of combat effectiveness commensurate with mission requirements and returning.

Overview Of The Proposed Procedure For An Integrated Production And Download Scientific Diagram

9 Types Of Maintenance How To Choose The Right Maintenance Strategy Road To Reliability

What Is Preventive Maintenance The Beginner S Guide To Running Pms

9 Types Of Maintenance How To Choose The Right Maintenance Strategy Road To Reliability

Comments

Post a Comment